Supply Chain Resiliency is the capability of the Supply Chain to be prepared for unexpected risk events. It is the Supply Chain’s ability  to respond and recover quickly to potential disruptions. It can return to its original situation or grow by moving to a new, more desirable state in order to increase customer service, market share, and financial performance.

to respond and recover quickly to potential disruptions. It can return to its original situation or grow by moving to a new, more desirable state in order to increase customer service, market share, and financial performance.

Resilience is currently an increasing concern in the Supply Chain caused by globalization. The Supply Chain is globally being subject to diverse types of disturbances. The largest disruption so far in the global Supply Chain in modern history was the earthquake and tsunami in Japan in March 2011. With the rising level of logistical complexity, the resiliency of the Supply Chain has not kept pace. These disturbances need to be handled in the right way, compelling the use of tools and approaches that can support resilient Supply Chain decisions.

With the onset of the COVID-19 pandemic, resiliency in the Supply Chain is further emphasized.

Understanding Supply Chain Resilience

The risk of Supply Chain disruption is increasing. A recent study by Aon Risk Solutions showed that the percentage of global companies reporting a loss of income due to a Supply Chain disruption increased from 28% in 2011 to 42% in 2013. The MIT Scale Network Study further showed that many large companies are unable to create contingency rules and procedures for operations during a complex, high-risk event.

According to the MIT study, approximately 60% of surveyed managers either do not actively work on Supply Chain risk management or do not consider their company’s risk management practice effective. Managers have been found to be lacking in a framework that will guide them in the deployment of risk management practices. In fact, it has been noted that there is little understanding of risks resulting in a lack of knowledge of what kind of framework fits a particular Supply Chain dynamics.

For Supply Chain Management to keep up with the increasing level of logistical complexity, there is a need to reconfigure the Supply Chain.

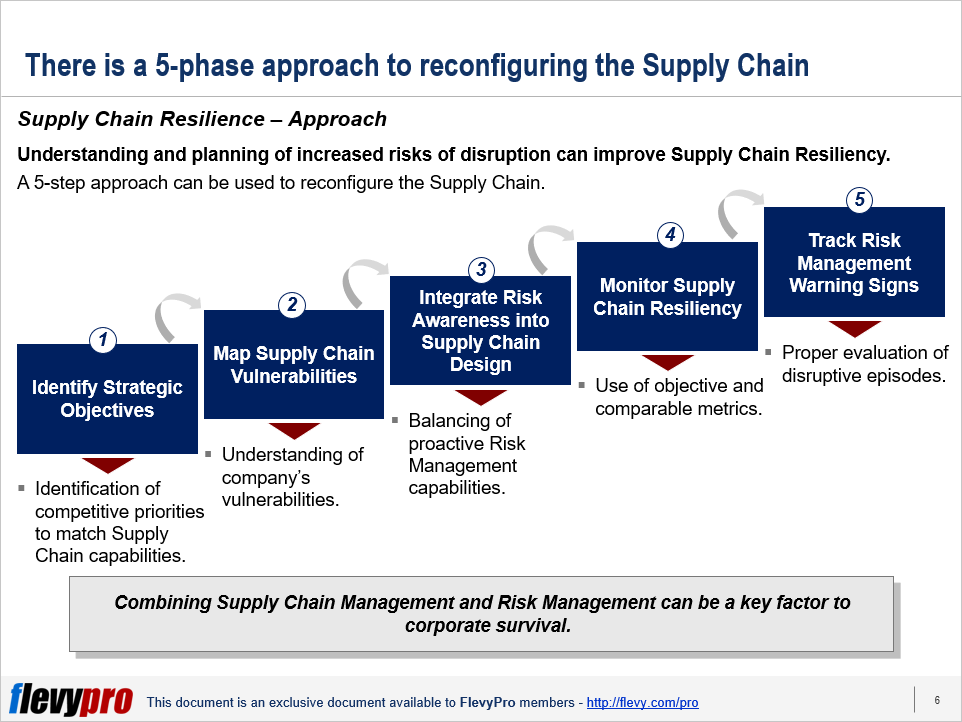

The 5-phase Approach to Supply Chain Resilience

In 2005, Cisco had difficulty coping when Hurricane Katrina struck. The Supply Chain performance level was not maintained to cope with the sudden surge in orders for new equipment to replace damaged telecommunication infrastructure. The Cisco teams cannot locate all products in the Supply Chain or understand the financial impact of emergency sales. However, in 2011, that was a turning point for Cisco. Cisco had deployed a very solid Supply Chain resiliency program that addressed the impact of external vulnerabilities and the aftereffects it caused to the Supply Chain.

Cisco has succeeded by executing a 5-phase approach to Supply Chain Resiliency.

In reconfiguring its Supply Chain to make it more resilient, Cisco first identified its strategic objectives.

Phase 1: Identify Strategic Objectives. The first phase is focused on identifying competitive priorities for particular product categories. It matches priorities with Supply Chain capabilities.

Through Strategic Planning, Cisco was able to build its competitive advantage which depended on its ability to match global opportunities to outsource production with global market opportunities. This is known as the Cisco Lean Model.

Phase 2: Mapping Supply Chain Vulnerabilities. This focused on understanding the company’s vulnerabilities. Supply Chains are vulnerable on many fronts—political upheavals, regulatory compliance mandates, increasing economic uncertainty, natural disasters, etc. Being aware of the vulnerabilities will enable the organization to come up with the appropriate design to achieve Supply Chain Resiliency.

In undertaking the second phase, Cisco focused on supporting a responsible global Supply Chain characterized by product differentiation, high value, and high margins. Mitigation measures were also implemented to make a resilient Supply Chain.

With the 5-phase approach, Cisco was able to achieve a resilient Supply Chain capable of effectively managing disruptions. It has also prepared them in addressing risk management warning signs and deploying the appropriate reactive tools to every kind of significantly disruptive event.

Interested in gaining more understanding of Supply Chain Resiliency? You can learn more and download an editable PowerPoint about Supply Chain Resiliency here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Comments